1295: The Year of the Galleys

Share

- Details

- Transcript

- Audio

- Downloads

- Extra Reading

This lecture is about an extraordinary set of English shipbuilding accounts dating from the 1290s, when the ports of London, Southampton, Ipswich, York, Newcastle and other places constructed eight war galleys for King Edward I. These accounts are the earliest-known significant English shipbuilding records, but they also have a wider historical importance, offering a unique ‘snapshot’ of late 13th-century England. The lecture will consider the maritime aspects of the project, but will also show what the material has to tell us about the nature of working life for ‘ordinary’ people, from shipwrights and blacksmiths to the women employed to clear the shipbuilding sites of wood chips. The City of London built two of the biggest galleys, so ‘The Year of the Galleys’ will have an added interest for Gresham audiences.

Download Transcript

*includes time to build any auxiliary barges and boats ** amounts of timber and board were acquired before the start of the building work *** with interruptions **** account runs to 44 weeks, covering repair work + to nearest £ (total project costs, including barges, etc) The building sites and the supply of materials In terms of space and location, all that a medieval shipwright really needed for constructing a ship was a vacant site close to the water. It is not possible now to point to the exact sites where any of the 1295 galleys were built, but we can at least localise a few of them. The London galleys, for instance, were built ‘next to the Tower’. The medieval fortress was surrounded by walls and a large moat, so unless the work was carried on in one of the areas outside the Tower precincts, the most likely candidate for the building site is a narrow strip of land that once separated the southern Tower moat from the Thames. At its eastern end this strip was about 30-40 m wide, just about enough room for a building a galley. The Newcastle galley was launched into Pandon Brook, on the east side of the city, so must have been built close to the stream. The location of the York galley site is discussed below. There is little indication as to exactly where the other galleys were built, although it is probable that the Lyme vessel was built on the foreshore. Four of the accounts tell us something directly about the nature of the building sites. The table below summarises the information. The absence of information about the other sites does not necessarily mean that they were without facilities or physical security, as the amount of detail offered varies from account to account. However, with so much valuable material lying around, the potential for theft was clearly high. Watchmen were employed at Ipswich, London, Lyme, Newcastle and York, working ‘day and night’ as the accounts put it. At London a man named Thomas Pope and his boy kept watch on the materials for both galley projects; at York, John of Acaster undertook this role, but there were also a couple of others, Robert the Clerk and Little Andrew (Andrew le Petyt), who did similar work. The galley accounts also tell us something about local transportation. At York, the work on the galley involved over 40 journeys by boat or ship along the Ouse, carrying timber and other materials from woods and other places downstream of the city. Carts were used, but mainly for moving felled timber from the woods to the river – on one occasion, 37 carts were hired for the work. However, most of the goods moved within the city itself were carried by hand. A gang of porters, led by a man named Adam le Pinder, trudged to the galley site carrying timber, nail, coals and other materials, and they also acted as stevedores loading and unloading boats. As at York, river transport and porters were used extensively for building the 2nd London galley, the latter employed on at least 45 occasions to carry items to the site. The porters operated over distances of up to a mile or so, for example carrying 1,000 trenails from Baynard’s Castle at the other end of the walled city. On another occasion a group of eighteen men lugged a ‘great timber for the keel’ from Holy Trinity Priory in Aldgate to the Tower. The great difference between the London and York projects as regards transportation lay in the greater degree to which carts were used at London. These were hired in great numbers, taking timber from the woods to boats on the river, but also carrying it directly from the woods to the capital. In some cases, timber went at least ten miles by road to London, a contrast to York, where virtually all of the heavy materials entering the city came by water (interestingly, packhorses are not mentioned in any of the 1295 accounts). The key material for shipbuilding was of course timber. Much of the timber used for the 1295 galleys was green, felled for each project by shipwrights, other carpenters and woodsmen. Using large quantities of unseasoned timber for shipbuilding is not a good practise, as it tends to degrade faster than seasoned wood, but it seems to have been a common feature of medieval ship construction. The raw timber was mostly shaped on the building site, by both axes and saws. Boards were often bought in ready-made, but were also manufactured for each galley, either sawn, or cleft from logs using axes and wedges. The seams between the boards of a hull were caulked or waterproofed with a mixture of wool or tar, called ‘wiveling’ at London and ‘blare’ at York and Newcastle. This was used in large amounts, along with other waterproofing measures such as coating the hull with pitch, tar and tallow (animal fat). Medieval vessels must have had a pungent smell. The ropes, cables, masts, sailcloth and other rigging gear were expensive, and not always easy to obtain. Even in the great port of London, the galley builders had to go to Faversham and Sandwich in Kent for most of their rigging items. All canvas used in England was imported, but there was a local substitute, a woollen cloth called ‘bever’ or belver’. This was used both for sails and for the tentlike tilts that covered the galleys in harbour. The medieval ship was mostly an organic artefact, even using wooden nails or trenails in the hull. However, there was also one major inorganic component: iron. In every one of the detailed building accounts, we find evidence of huge amounts of ironwork, mainly in the form of nails. The clenchnails or ‘seamnails’, with their roves were very important (and could be expensive, because they had two components), but so too were metal spikenails or ‘spikings’ and various other fasteners of uncertain type. Smiths will have been employed on all of the projects, and for the Newcastle galley they fashioned around five metric tonnes of iron into clenchnails for the galley. On top of this, another 26,000 nails of various kinds were used in the vessel. The Newcastle Galley was not alone in consuming such prodigious numbers of fasteners: the first London galley had over 27,000, the second London galley used over 38,000 and the York galley, more than 31,000. The shipwrights It is often said that, in the days before shipbuilding treatises and ships’ plans, shipwrights built vessels ‘by eye’. This was certainly true, and the process is still used by some boatbuilders. In illiterate shipbuilding cultures, traditional ideas about the proportions for different designs were transmitted verbally, or through the use of simple tools like the Scandinavian ‘boat ell’. However, there is evidence that by the later Middle Ages, some north European shipbuilders were using more complex design processes. The 1295 accounts do not solve the problem of how medieval ships were designed, but they do tell us that the master shipwrights in charge of the projects must have been highly numerate, and perhaps even literate. The 1295 accounts record many items bought in their hundreds and even thousands, from nails to ells of sailcloth. It is clear that the master shipwrights were used to working with ‘big numbers’. It is also evident that the use of formal measurements was a normal part of their work, for the accounts contain many references to timbers and boards measured in feet. To take a few examples, the hull and defensive upperworks of the Ipswich galley contained over 9,200 ft (2,804 m) of boards, the Southampton galley used over 12,400 ft (3,780 m) of planking, and the keel of the Newcastle galley was made from two massive timbers with a combined length of 108 ft (32.9 m). Such precision suggests that shipwrights knew how to use items of measured length in the construction process, and the York account even indicates that the dimensions of the galley were measured out on the ground. The document includes a reference to the purchase of a ‘measuring rope’ for ‘marking out’ or ‘ruling out’ the galley. Two small measuring ropes were also bought for the barge that was built alongside the galley. We cannot be sure if the master shipwrights were literate, but overseeing the construction of a galley was not just a huge engineering task, it also carried heavy management and accounting responsibilities. To take one example, at York, Henry Hellewarde managed and co-ordinated the activities of over fifty shipwrights, to say nothing of other workers. The financial side of the work was also complex. The 2nd London galley account records over 1,500 individual payments and that for York has over 1,250. Even though accounts were literally ‘audited’ (i.e. read out), it would have been a real advantage for a master shipwright to be able to read the documentation, to avoid being defrauded or defamed. Certainly Henry Hellewarde, for one, was an astute businessman. Out of more than 240 people involved in the York project, he was the fifth highest-earner. Such success would seem unlikely if he was unable to understand what the project clerk was writing down. One might argue that these master craftsmen were exceptional men, not typical of their profession in England at that time. The London and Southampton projects were supervised by shipwrights from Bayonne, and it is possible that Henry Hellewarde was of foreign extraction. However, there seems little reason to doubt the ‘Englishness’ of William of Wainfleet, builder of the Newcastle galley, or the four master shipwrights from Sussex and the Isle of Wight who worked under the Bayonnese at Southampton. Where we have the names of the actual shipwright teams themselves, it is clear that most of them were English. Foreign involvement was important in some of the 1295 projects, but it does not seem to have been widespread. The 1295 master shipwrights No doubt traditional design proportions played a big role in shaping the galley hulls, but the 1295 accounts suggest that even by the late 1200s, the use of formal measurement was also a normal feature of north European shipwrightry. The leaders in the trade were highly sophisticated craftsmen and equal, in their way, to the master masons who built cathedrals. The organisation of work on a shipbuilding site, and levels of pay, were conditioned by the technology of clinker construction. The table below shows the basic structure, with the highest paid, the master, at the top and the holders and the bottom end of the scale. Some accounts also show a few boys assisting the shipwrights, paid at a rate lower than the holders, and these may have been apprentices. The organisation of the shipwright’s trade Master Boarder Clencher Holder The accounts have a lot to say about about the technology of clinker construction, but they also show the how the shipwrights’ work was organised on site. Three of the accounts (Newcastle, York and 2nd London Galleys) are arranged on a clear week-by-week basis, which makes it possible to work out how many shipwrights were employed in a given week, and for how long. The resulting calculation of man/days makes it possible to reconstruct the rhythm of the work, the rise and fall of the collective effort needed to build the vessel.

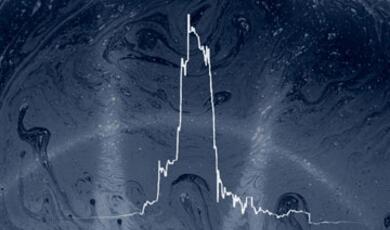

The total numbers of shipwright man/days needed to build the galleys up to the point of launching were broadly similar at York and Newcastle, but very different from the figure for the 2nd London galley. If one divides the man/day data into tenths for the purpose of comparison, then the patterns of effort at York and Newcastle are also closer to each other than to that at London. The overall pattern of work was much more consistent in London, with few of the sharp rises and falls seen in the graph lines for the other two. This apparent north/south divide was not due different technology or ship types – these were all clinker-built galleys. The explanation may lie in the management arrangements among the shipwrights, as the York and Newcastle projects had single master shipwrights in overall control, whereas it seems that the 2nd London galley was effectively the work of a team three men, headed by Arnold of Bayonne. Similar ‘multiple master shipwright’ arrangements were used on the Lyme and Southampton projects, and appear to run counter to our notions of the hierarchical nature of medieval society. The main advantage of this management approach may have been that it allowed for much more consistent supervision of the work than was possible for one master shipwright, and this could explain the more concentrated level of effort apparent in building the 2nd London Galley. Whatever the real explanation, managerial relationships in a medieval shipyard were more complex than we might otherwise expect. Another, less surprising, thing that emerges from the 2nd London and York galley accounts is that shipwrightry could be a family business. English surnames were still evolving in the late 13th century, but analysis of the names of shipwrights suggests that about 20% of the London shipwrights and 27% of the York shipbuilders worked either definitely with relatives or at least with people of the same surname. The York master shipwright Henry Hellewarde was accompanied by another shipwright, Walter Hellewarde, and two boys named John and Henry Hellewarde junior. They were probably all his sons. Various other workers were to be found on the galley projects besides shipwrights. The felling and shaping of timber in the woods was carried out by carpenters, some of them certainly shipwrights. The additional shaping of timber on the galley site was also undertaken by carpenters, and sawyers worked both in the woods and on site, in teams of two. There was no separate caulking trade in England at this date, so the work of waterproofing the plank seams must have been undertaken by the shipwrights, People were sometimes employed to spin wool, hair or moss into thread to be used in caulking, with others heating pitch and tar for the work. At London all of the ‘wiveling’ – the wool or hair – was bought in, but at York several men spent weeks on site turning the material into thread. Given the amount of iron nails and other ironwork needed by the galleys, smiths were also important figures in the shipbuilding process. At York, a purpose-built smithy was erected on site and a master smith named William of Hessay moved an anvil and other gear there from his premises in Micklegate. The smithies for the Newcastle and London galleys were offsite, perhaps in the Tower itself in the case of London. Ironworking was hard, but profitable work, at least for the master smiths. William the smith at London earned slightly more than the master shipwright Arnold of Bayonne, and at York the smith William of Hessay was the seventh-highest earner on the project. The direct participation of women in the galley projects was minimal. A couple of female carters seem to have been used to move timber for the second London galley and the two men who painted the Newcastle galley had a female servant assisting them. At York, a number of women were paid 1d a day each to clear chips of wood from the building site as the construction of the galley neared its end, a rate that was probably barely enough to keep body and soul together. Aside from the shipwrights, the biggest teams of workers involved in some of the projects were labourers employed to dig launching channels. It took 57 men three days to dig the launching channel for the 2nd London galley (171 man/days), but 290 man/days to do the same at York – perhaps they had to hack through the remains of Roman buildings in the city. Who benefitted most financially from these projects? The answer is a simple one – rich merchants, officials and leading craftsmen. Analysis of the total earnings of named individuals involved in the York and 2nd London projects certainly suggests that this was the case. The table below shows some remarkable similarities between the numbers of people in different earnings brackets at London and York (people earning less than 6s have been excluded, as in most cases their names are not given, making it impossible to work out their total earnings):

At York, the group earning 101s or more was dominated by people who supplied materials (cordage, metal timber and other items) or occupied supervisory positions. The highest-earning person, Walter Cathon, supplied rigging and other gear, but second and third highest earners were two people who acted as both project officials and suppliers, Henry the Goldsmith and Thomas of Whitby. Some of their income came from project pay, but a substantial amount also derived from the sale of materials. The ‘101s+’ group included just two manual workers, the master shipwright Henry Hellewarde and the master smith William of Hessay. At London the same group was dominated by suppliers, with Arnold of Bayonne as the sole artisan (Arnold of Bayone’s total earnings for the shipwright’s work on the two London galleys came to 180s, just over 2s less than Henry Hellewarde’s earnings at the York for one galley – Hellewarde seems to have been a canny operator). However, there are signs of some regional differences, at least as regards shipwrights, whose pay was lower at York than at London. Whilst 60% of the London shipwrights earned between 11s and 40s, only a third of the York shipwrights were in this bracket, and nearly half of them received less than 6s in total earnings. The casual workers employed on all of the projects, porters and others, generally earned less than the shipwrights. This underlines the small, but significant difference that existed between people who had a skill and those who were only labourers. The technology of the galleys Much of research into the 1295 galleys, including my own earlier work, has focussed on trying to find out what the galleys were like. At one level, this is absolutely clear: all of the vessels were clinker-built, one-masted and carried large sets of oars. In most cases, the construction of the galley was followed by the building of a smaller oared barge, to act as a support vessel (the table on the next page summarises some of the key technical features of the galleys and barges, where known). None of the 1295 accounts contain direct statements regarding the exact sizes of the galleys, though the numbers of oars gives some comparative data. A one hundred-oar galley would have 50 rowers on a side. The historian R C Anderson long ago suggested that a possible rule of thumb would be 2 ft of keel for every pair of oars, assuming the rowers were on staggered benches, so a 100-oard galley would have a keel of 100 ft.. However, this conjecture may have its problems (see below). The only 1295 galley for which we have an approximate stated length is the Newcastle vessel, which had a keel made up of two pieces of timber, of 56 ft and 52 ft in length. Factoring in an overlapping scarf joint to fix the two together, this would make a keel of about 100 ft (30.5 m). The hull would have been longer than this, allowing for the rake of the stem and sternposts. In the 1930s W R G Whiting produced an interesting conjectural reconstruction of the Newcastle galley, which had a total length of about 135 ft (41.2 m). Some technical information about the galleys (nk = not known)

* these figures probably include an allowance of 20-30 oars for the respective barges ** reference to the manufacture of hasps and staples at an advanced staged of the work (week 21), items known to have been used in breastworks *** approximate figure – the galley put to sea with a crew of about 80 men Despite the fact that the Southampton and Lyme galleys did not meet the oar-power requirements in the 1294 order, at least five of the others came close to their target or exceeded it. However, it is clear that the rowing arrangements of the galleys must have been rather complex – they were not just rowing boats ‘writ large’. The Newcastle galley had 66 oars that were 22/23 ft in length and 39 that were 16/17 ft long, plus another 23 of unknown length. The different oar lengths point to some kind of staggered rowing system, with two rowers on each bench, and conjectural reconstructions of this type of rowing system have been made. As Gillian Hutchinson has observed, some sort of staggered rowing system must have been general among the bigger 1295 galleys. If the men had been seated the one behind the other, it would have been difficult to fit 50 or more rowers into each side of a ship with a keel length of 100 ft of so. This issue remains uncertain, and may only be solved by the discovery of the remains of a medieval English galley or by experimental work with models or a reconstruction. The evidence for the steering gear of the galleys is incomplete, but it is apparent that two had pairs of side rudders and one of them, the Lyme galley, had a combination of a side-rudder and stern rudder (the side rudder was a form of ‘steering oar’ mounted on the side of the vessel; the stern rudder was mounted on hinges at the sternpost, in line with the keel). The stern rudder had been around for at least a century by the time of the 1295 galleys, but this pairing of the two types suggests that it was not completely trusted, at least for big oared ships. Experiments with a side-rudder on a reconstructed Viking ship has shown that it can be a very effective steering method. However, such a device was undoubtedly more vulnerable to storm and battle damage than a stern rudder, and there are signs that by the 1330s it was falling out of general use in England. The information in the accounts about the defensive structures of the galleys is likewise limited. However, breastworks, or hurdis, seem to have been widely used, both on the galleys and the barges. These were light wooden blinds that were mounted on the gunwale and protected rowers and other crew from projectile weapons. They could be opened or lifted out to allow people out of the vessel, or to give a clear shot for bowmen, for some of the accounts mention hasps and staples being bought for use in the hurdis. They were probably similar in general terms to the wooden defensive ‘blinds’ found in the waist of the Mary Rose (sunk 1545), some of which were removable. Two of the galleys, those of Newcastle and Southampton, each had three sets of castles. These must have consisted of a forecastle at the bow, an aftercastle at the stern and a topcastle at the head of the mast. Pictorial evidence shows that this kind of arrangement had existed since at least the late 12th century. The fore- and aftercastles were set up on posts and probably resembled watchtowers. Castles were essential for any large warship and it is likely that all of the 1295 galleys had them. Galleys were fairly low-built vessels, and could be overtopped by big sailing ships, which stood higher out of the water. Hull and superstructure heights were critical factors in medieval sea warfare, as a larger vessel would be able to rain down arrows, rocks and other projectiles on an smaller opponent. Fighting castles at least went some way to ‘level the playing field’ for oared warships. The sail data is insufficient to allow us to say much about the sails used in the galleys. Sailcloth was measured in ells, a unit nominally of 45 inches (1.14 m), but one that before about 1400 sometimes also denoted a yard (1.09m). It is clear that large amounts of cloth were bought for the sails of the London and Dunwich galleys, but the figures alone do not reveal anything about the actual sizes of the sails. All that we really know is that they must have been very big. Information on a sail made for an 80-oar galley in the 1330s, backs this up, for this measured around 22/23 m on a side. The masts and yards carrying such sails also had to be very large, and some rigging data for the second London galley suggests that it had a mast at least 100 ft high (30.5 m). Just as the steering gear used in some of the galleys was transitional, so was some of the rigging. When a square-sailed vessel attempted to sail to windward, it needed some method to prevent the leading edge of the sail from collapsing in the wind. The Viking solution to this was a wooden spar, latched to the windward edge of the sail and known in 13th-century England as a ‘lof’. However, a new device had been invented by about 1200, the bowlines. The bowlines were ropes led forward from each edge of the sail to a spar projecting from the bow (the bowsprit). When a vessel was sailing to windward, the bowline of that side was pulled taut, to keep the edge of the sail rigid. At least five of the 1295 galleys had lofs, but three of them also combined this with bowsprits and bowlines. Like the side rudder/stern rudder combination, this was perhaps another example of seafarers taking a ‘belt and braces’ approach to the technology that they used. Some of the galleys were certainly equipped to provide hot food for their crews, although there is no evidence that there were cooking hearths aboard the vessels, so any cooking was probably done ashore. The Newcastle galley carried three large brass cauldrons and six brass pots weighing 157 lb (71.4 kg) in total, and the crew dined off eighty dishes and forty saucers. The galley also had a handmill for grinding flour, and six iron griddles, presumably to make oatcakes. Other galleys also had eating and drinking equipment: there was a strong practical requirement to ensure that the crew were well fed and watered. Life aboard the galleys, or any medieval vessel, must have been very hard. Cloth tilts were often provided to act as coverings for the crew when a galley was at anchor, but the decks will have been very exposed at sea. Galleys operating off the coast probably needed to put into shore frequently to refill their water barrels, but it is also clear that they could make long sea passages, some going as far as south-western France. Even though they carried many oars, it is likely that most of the time the galleys moved under sail. The human engine had its limits and it is probable that oar power was mainly reserved for pursuit, flight or battle. Reconstructing the past It may be possible to reconstruct a number of specific events from the 1295 galley accounts. The York document, for example, offers some interesting evidence regarding the way in which the galley was launched, and may point to the location of the building site. The river Ouse at York was spanned by a single bridge in medieval times, with a chapel dedicated to St William of York standing on the north side of the western end. Early on in the 1295 York galley account, there is a statement that a ship loaded with timber brought upriver from south of the city was pulled under the bridge in order to reach the building site. This shows that the site was to the north of the Ouse Bridge. The galley site itself was set back from the river, as the digging of the launching channel shows. The launching took place in week 25 of the project. Six men, a mere handful, were paid for actually getting the galley into the water, although some shipwrights were also on hand. This sounds like a ridiculously small number of people for launching a heavy vessel some 25-30m in length, but the men probably had mechanical assistance, as the project had borrowed a windlass (ferne) from the local Franciscan friary. Cables and ropes for the launch were laid across the river, but some others were also carried up to the chapel on the Bridge, presumably to provide additional purchase. This suggests that the galley site was both close to the Bridge, and lay on the eastern side of the river - i.e. the opposite one to the chapel – and also implies that the windlass was on the west bank. The launching channel seems to have been floored with wooden hurdles and timbers, greased with about 16 litres of oil. The York galley slid into the Ouse between 15 and 17 September 1295, probably with banners fluttering from four lances bought for the purpose. A large amount of ale was provided for everyone involved, but whether this was for celebration or merely rehydration, is not clear. What became of the galleys It is not possible to track the service lives of the 1295 galleys in any detail, but there are some fragmentary pieces of information about what happened to them. Their early voyages were not always successful, and several of them needed repairs not long after they were completed. The first London galley suffered perhaps the worst damage: after being caught in a storm at sea it needed hull repairs that were equivalent to about 25% of the original building cost. Other galleys got off to a better start. After being launched in the summer of 1295, the York galley was taken downriver to Swinefleet, west of Hull, to be completed and rigged. This was a slow process, not finished until early 1296, but in February and March of that year it seems that the galley was put through several short trial voyages, with crews ranging in size from 36 to 80 sailors. Subsequently, it was sent on an expedition to Holy Island off the Northumberland coast, in support of Edward I’s invasion of Scotland. A man named Hugh Keling was the master, but Henry Hellewarde was also aboard, probably there to undertake what modern house builders call ‘snagging work’. We do not know what became of the London, Dunwich and Ipswich galleys, though the Grimsby and Newcastle vessels are known to have taken part in coastal patrols between King’s Lynn and Berwick in the late summer and early autumn of 1295. The Newcastle galley served in the Scottish expeditions of 1296 and 1297, but by 1301 it was in bad condition. In that year the galley, barge and boat were sold back to Newcastle for £40, a depreciation of around 80% in six years! The Lyme galley took part in two expeditions to Gascony in 1296 and 1297, the latter one in company with the Southampton galley. The Lyme galley was not completed until 1296, and there is a rather pathetic sequel the tale of its construction. After the vessel was finished, the bailiff of Lyme, Geoffrey the Cook, petitioned the king to ask for payment. He had given tally-sticks – notched wooden receipts – for goods and services received to the ‘poor people of the country’, but had nothing with which to pay them. They, in return, were saying that Geoffrey had already received the money from the Exchequer and was keeping it for himself, putting him ‘in great slander’. More than twenty years were to pass before Lyme finally got the money it was owed. The ‘year of the galleys’ has given us the earliest-surviving detailed sources for shipbuilding in England, documents that are also significant for European maritime history. However, their broad regional spread and the level of information that they provide about working life means that their interest and importance reaches beyond the maritime sphere. Although they were compiled for the starkly utilitarian purpose of recording expenditure, the 1295 galley accounts now also provide a compelling snapshot of ordinary people and daily life in England more than seven hundred years ago. © Dr Ian Friel 2013

This event was on Thu, 31 Oct 2013

Support Gresham

Gresham College has offered an outstanding education to the public free of charge for over 400 years. Today, Gresham plays an important role in fostering a love of learning and a greater understanding of ourselves and the world around us. Your donation will help to widen our reach and to broaden our audience, allowing more people to benefit from a high-quality education from some of the brightest minds.

Login

Login